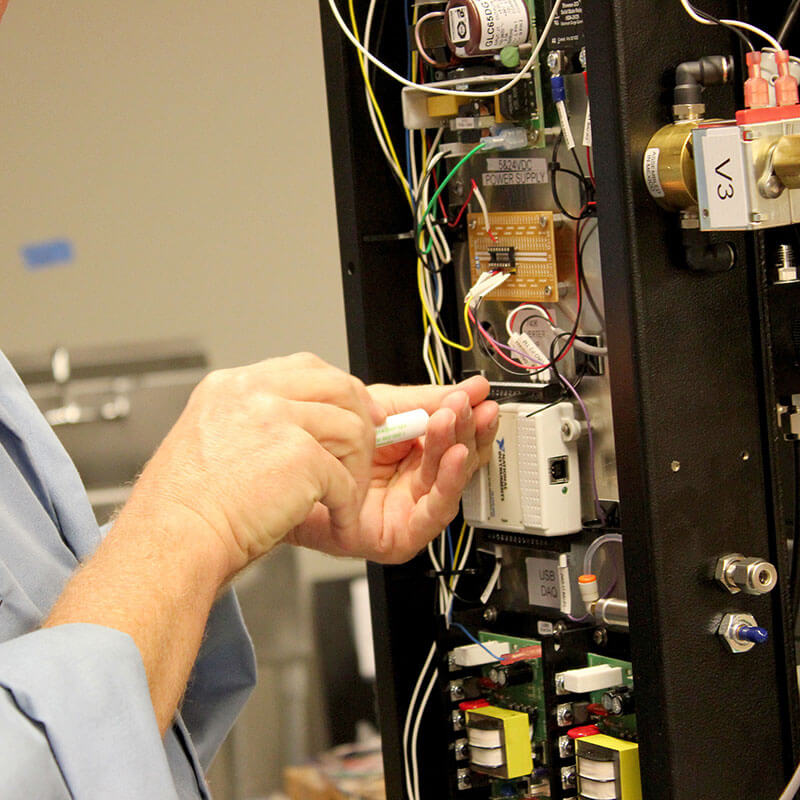

For over 40 years OFI Testing Equipment (OFITE) has provided instruments and reagents for testing drilling fluids, well cements, completion fluids, and wastewater. In addition to these product lines we also offer a range of instruments for core analysis. From our manufacturing facility in Houston, TX we provide customers all over the world with quality products and exceptional service.

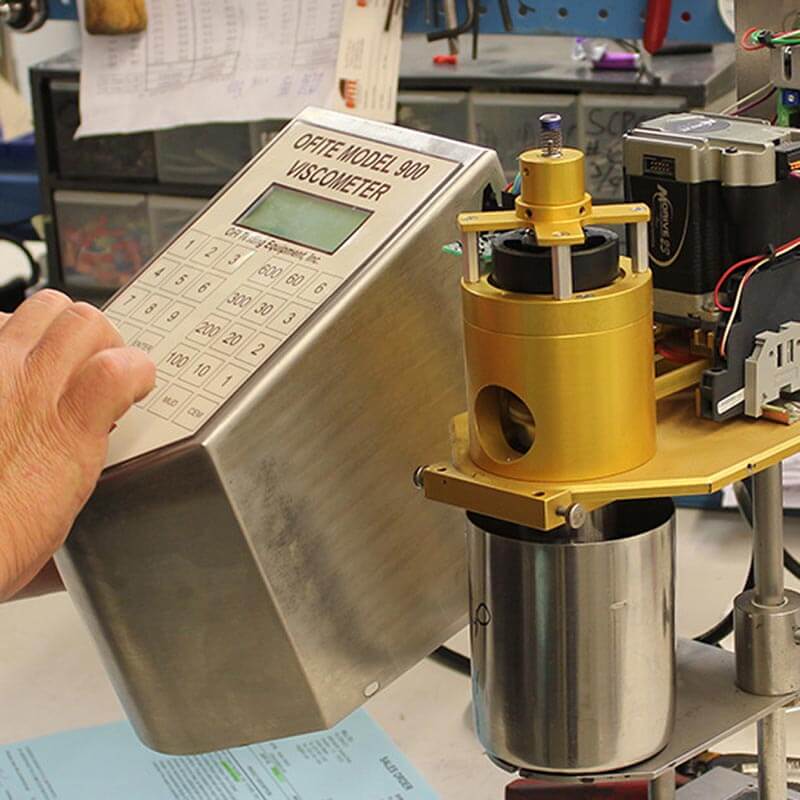

Our drilling fluids testing equipment product line includes innovative designs such as the Model 900 Viscometer, which showcases our ability to develop new technology to meet customer and industry demands. We also offer Retorts, Aging Cells, Roller Ovens, Mud Balances, Filter Presses, and all other instruments required to evaluate drilling fluid properties according to API Recommended Practice 13B-1 and 13B-2.

Our cement testing equipment product line includes innovative designs such as the Static Gel Strength Measurement Device (SGSM), a true OFITE innovation. We also offer Ultrasonic Cement Analyzers (UCA), Constant Speed Blenders, Automated HTHP Consistometers, and all other instruments required to evaluate cement properties according to API Specification 10.